Seiko has a rich history in chronograph innovation, and the Calibre 7018 is an excellent example of the brand’s engineering expertise. Part of the legendary 701x series, the 7018 movement is a vertical clutch automatic chronograph with flyback functionality, meaning the chronograph hand can be reset while running, an advanced feature at the time of production.

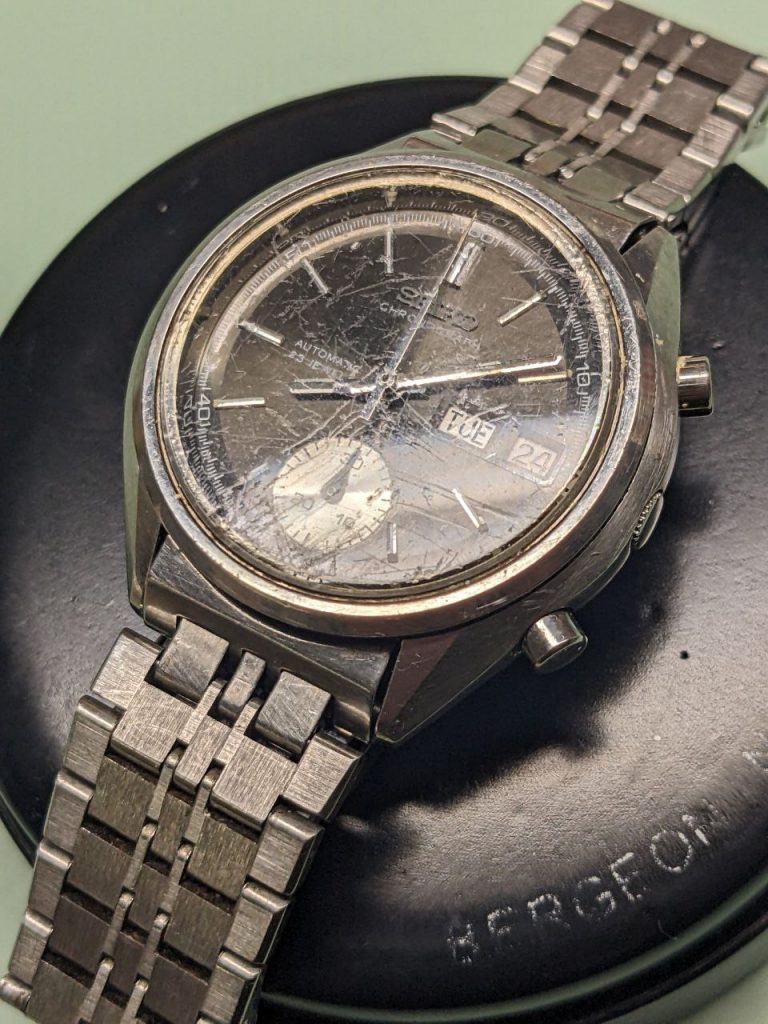

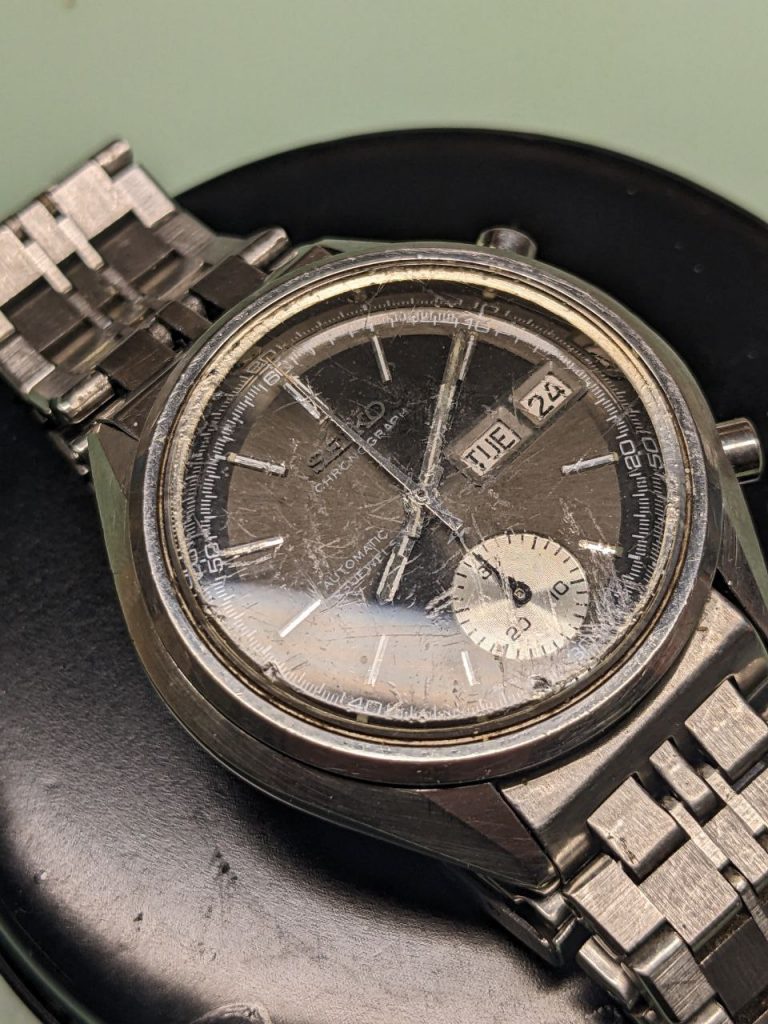

This particular Seiko 7018 Repair was a true survivor—having never been serviced, it had stopped running 10 to 15 years ago. Given the age of the watch and the fact that Seiko 7018 parts are extremely rare, we were fortunate that no replacements were needed. Instead, a full service and careful regulation were enough to bring it back to life.

A Brief History of the Seiko 7018 Movement

Introduced in the early 1970s, the Seiko Calibre 7018 was part of the 701x series, developed in parallel with the famed 6139 chronograph (one of the world’s first automatic chronographs). The 7018 is derived from the 7016, which features a dual register layout, whereas the 7018 simplifies the design to a single 30-minute chronograph counter.

Key innovations of the 7018 movement include:

- Flyback chronograph, allowing instant reset while running

- Vertical clutch engagement, reducing wear and improving smoothness

- Column wheel mechanism, ensuring precise chronograph actuation

- Slim profile, making it one of the thinnest automatic chronographs of its time

Despite its technical excellence, parts for the Seiko 7018 are incredibly difficult to source today, making restoration of these movements a challenge for watchmakers. Fortunately, this particular movement was in repairable condition, avoiding the need for hard-to-find replacements.

Diagnosing the Problem – Seiko 7018 Repair

When we received this Seiko 7018 repair, the watch was completely non-functional, having been stored away for over a decade. Initial inspection revealed:

- The mainspring was fully unwound, indicating a potential issue with power transmission.

- The balance wheel was free but sluggish, likely due to dried oil.

- The chronograph function was jammed, possibly from congealed lubrication.

- The vertical clutch and column wheel showed grime buildup, preventing smooth actuation.

With no visible damage to key components, we proceeded with a complete disassembly and service to restore functionality.

The Seiko 7018 Repair Process

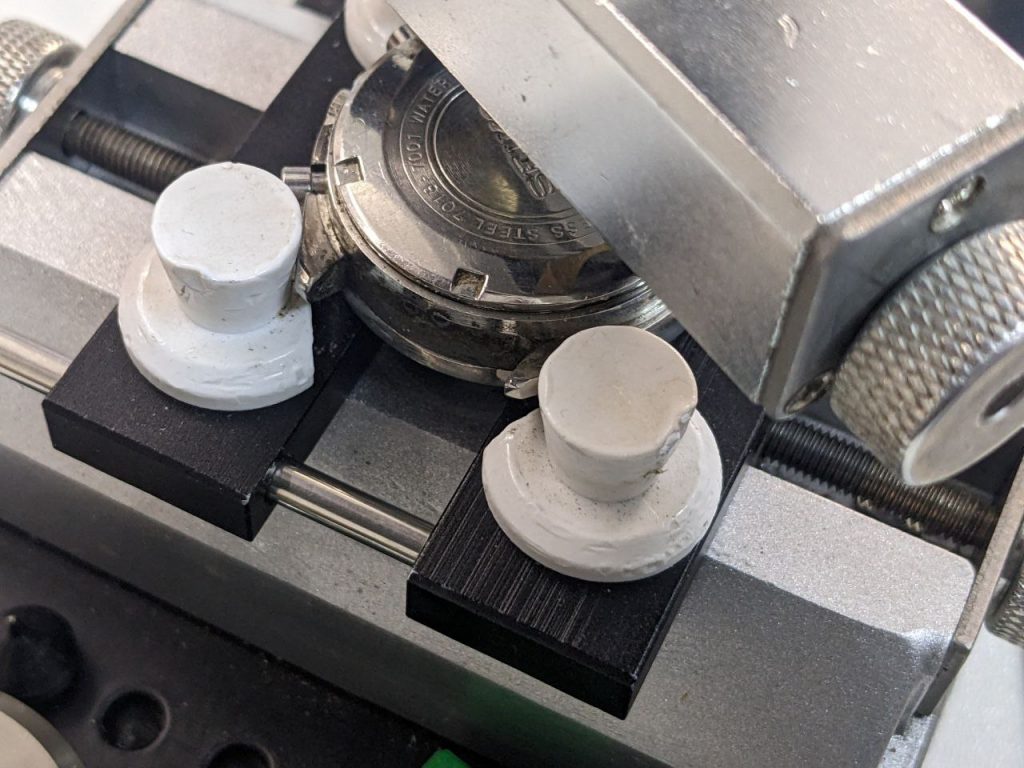

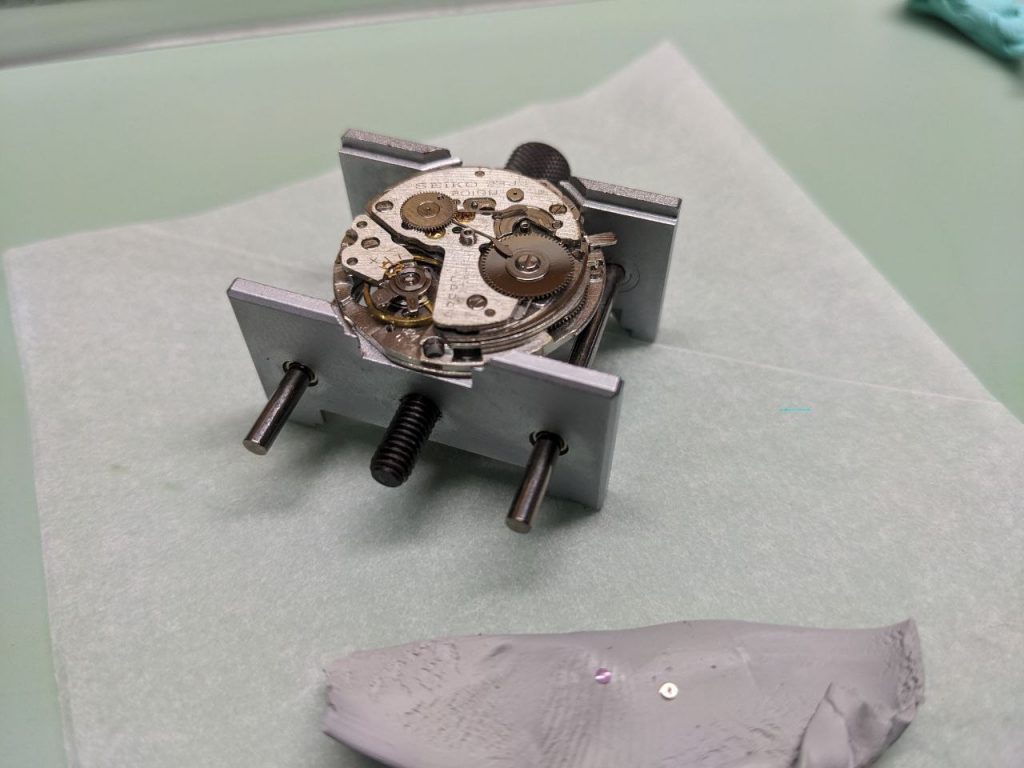

Disassembly and Cleaning

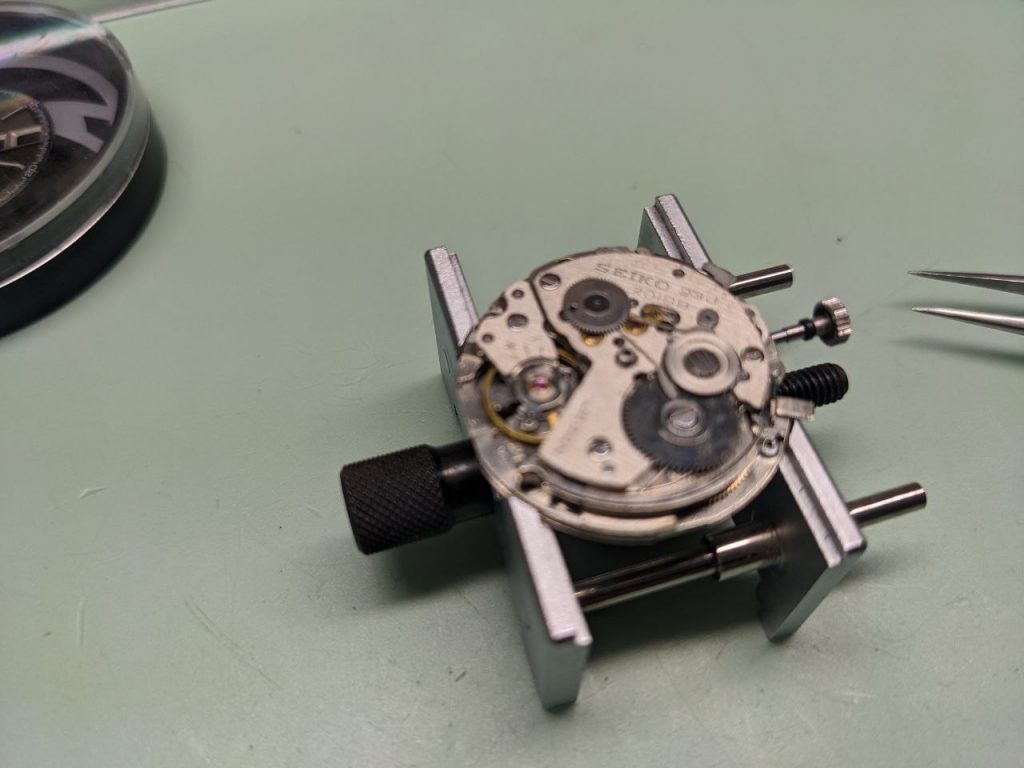

The 7018 movement is a compact and intricate chronograph, requiring careful handling during disassembly. Each component was removed, including:

- The main gear train, to ensure free movement of power transmission

- The vertical clutch mechanism, cleaned to restore proper chronograph engagement

- The column wheel, disassembled and re-lubricated for precise operation

- The balance assembly, checked for wear and properly cleaned

After disassembly, all parts underwent manual cleaning, including pegging the jewels and pivot holes to remove dried oil. This was followed by multi-stage vortex cleaning, with L&R fluids ensuring every trace of old lubrication and debris was removed.

Reassembly and Lubrication – Seiko 7018 Repair

Once cleaned, the movement was carefully reassembled, with fresh lubricants applied to key areas:

- Gear train pivots received a fine oil to minimize friction

- Escapement components were lubricated to optimize amplitude

- Chronograph parts, including the column wheel and vertical clutch, were treated with specialized grease to ensure smooth engagement

The mainspring was checked and found to be in good condition, so it was cleaned and reinstalled.

Regulation and Calibration – Seiko 7018 Repair

With the movement reassembled, we moved on to calibration. The beat error and amplitude were adjusted, with a notable increase in amplitude following lubrication and regulation. The watch was fine-tuned to ensure:

✅ Accurate timekeeping within vintage chronometer standards

✅ Smooth chronograph operation, with instant start/stop/reset

✅ Consistent power reserve, confirming the mainspring and barrel were functioning properly

Final Testing and Case Restoration – Seiko 7018 Repair

After movement calibration, the watch underwent multi-day testing, ensuring it kept accurate time and the chronograph engaged correctly.

The case was ultrasonically cleaned, removing dirt and grime accumulated over decades. Given the vintage nature of the watch, care was taken not to over-polish, preserving the original character of the case and dial.

The gaskets were replaced, ensuring the case had proper sealing. However, due to the age of the watch, pressure resistance was limited to splash resistance only, which was communicated to the owner.

Seiko 7018 Repair: A Classic Revived

The Seiko 7018 is a truly remarkable vintage movement, featuring innovations still relevant in modern watchmaking. Despite its age and lack of prior servicing, this particular watch was successfully restored without the need for rare replacement parts, a testament to Seiko’s build quality.

Now running at peak performance, this Seiko 7018 repair brings another iconic flyback chronograph back to life, ready for daily wear.

If you own a vintage Seiko chronograph in need of service, get in touch with us today. Follow us on Facebook for more updates on our latest restorations.

0 Comments